The insulation that holds its shape.

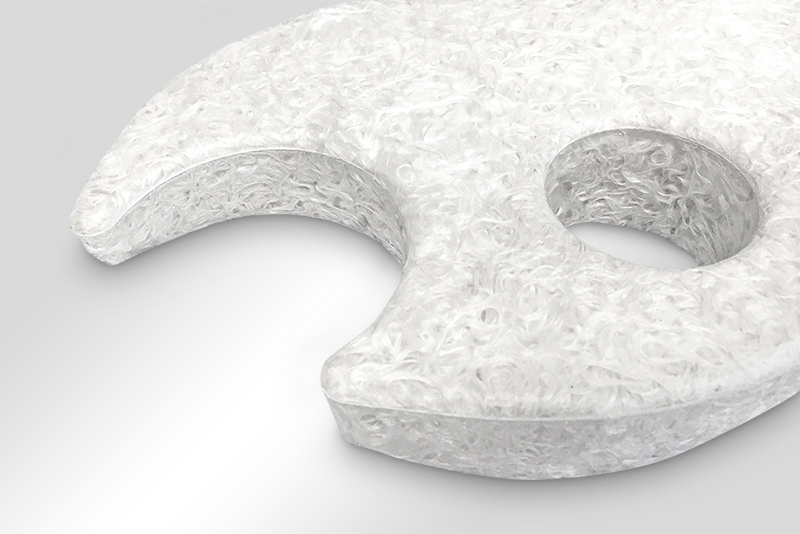

iTEX estop is an impressive cold-end insulation material that holds its shape, stays in position and is very easy to install. It is another product in the iTEX range that is made from textile glass fibers and is currently the only solution available that can homogeneously fill complex sound-absorber geometries – without organic binding agents.

The preexisting structure of the fibers enables very high dimensional stability supported by a colloidal, open-pore, inorganic (mineral) outer.

What’s more, iTEX estop is easy to process according to customer requirements. Thanks to the precisely defined external geometry and perfect-fit application, there are no complications from protruding fibers when welding together the casings of sound absorbers.

Additional benefits of iTEX estop include the high level of space-filling, even fiber distribution and improved fiber stability in the exhaust manifold. The material also meets all current manufacturer standards and can thus be put to a wide range of uses.

Technical properties

(version depends on application temperature)

| iTEX estop750 (up to 750 °C) |

iTEX estop600 (up to 600 °C) |

|

| Raw material: | ECR glass fiber | E glass fiber |

| Filament diameter (nominal): | 18 – 27 μm | 18 – 27 μm |

| Linear shrinkage: | ≤ 1% | ≤ 1% |

| Loss on ignition: | ≤ 2% | ≤ 2% |

| Chemical composition (ave. in weight %): |

1. SiO2: 60 +/- 2

2. CaO: 21,5 +/- 1,5 3. MgO: 3 +/- 1 4. Al2O3: 12 +/- 2 5. TiO2: 1,25 +/- 0,75 6. K2O+Na2O: < 1 7. Other: ≤ 2,5 |

1. SiO2: 54 +/- 2

2. Al2O3: 14 +/- 2 3. B2O3: 7,5 +/- 2,5 4. MgO-CaO: 23 +/- 7 5. K2O+Na2O: < 2 6. Other: ≤ 2,5 |