The easiest way to insulate components that carry hot gases is to place a glass- or silica fiber-based needle mat (iTEX mat) between the metal liner and the component. This provides excellent thermal and acoustic insulation. As the needle mat adapts to almost any contour, the fibers remain undamaged and the insulation effect is completely preserved.

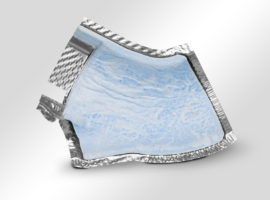

Using the iTEX mat as a basis, iTEX ST insulating shells are produced in a special molding procedure. With various additives included, a perfectly fitting solution is created that not only boasts improved thermal and acoustic performance but also greater mechanical stability. The additives enable the insulation shells to be designed to match the customer’s precise requirements, e.g. with a water-repellent coating (iTEX WATERSTOP). Besides a 100% reproducible contour that makes the shells easy to fit, they feature neatly sealed pinched edges that completely eliminate common welding problems in the metallic lining.