Thermal insulation and acoustic absorption at the highest level.

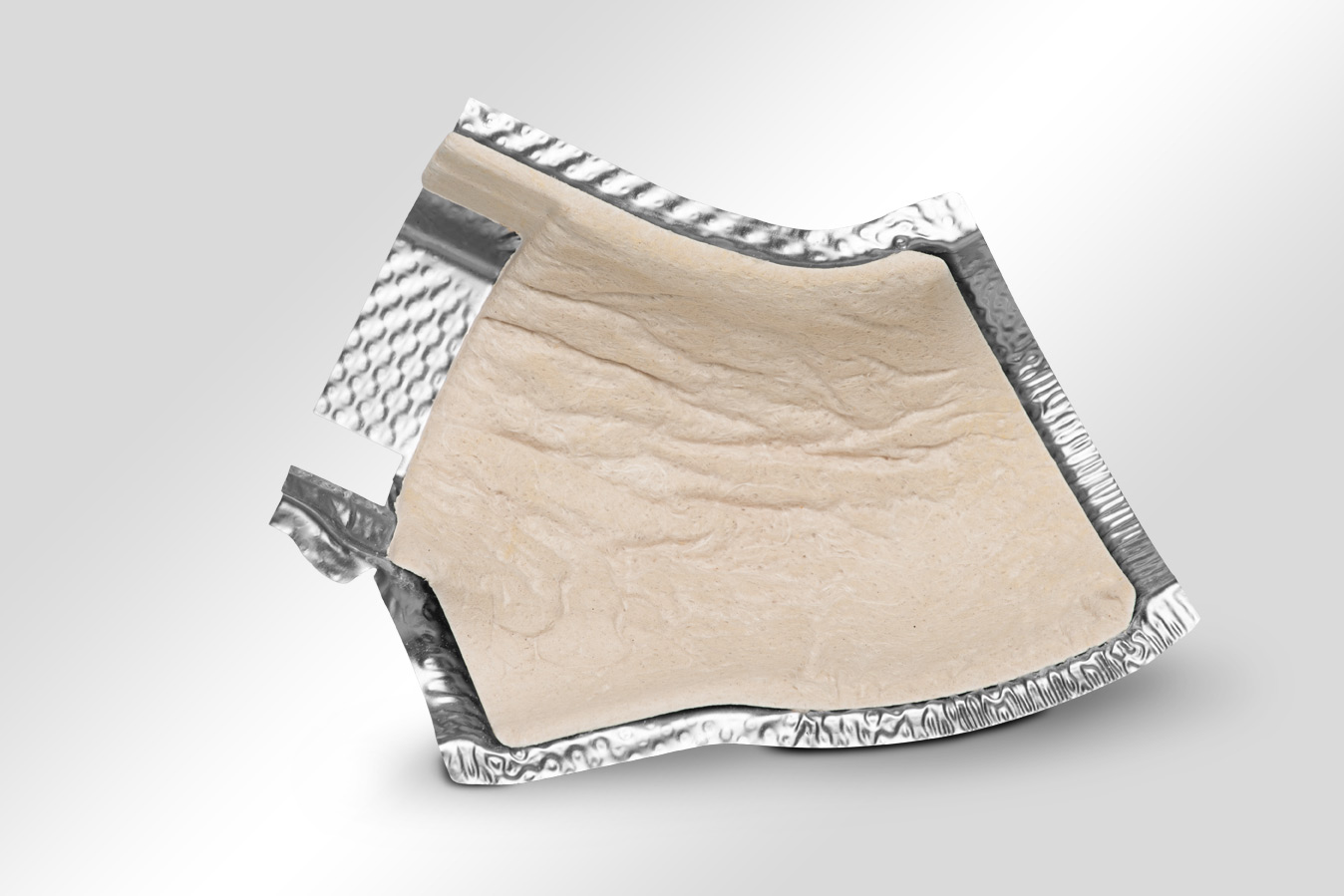

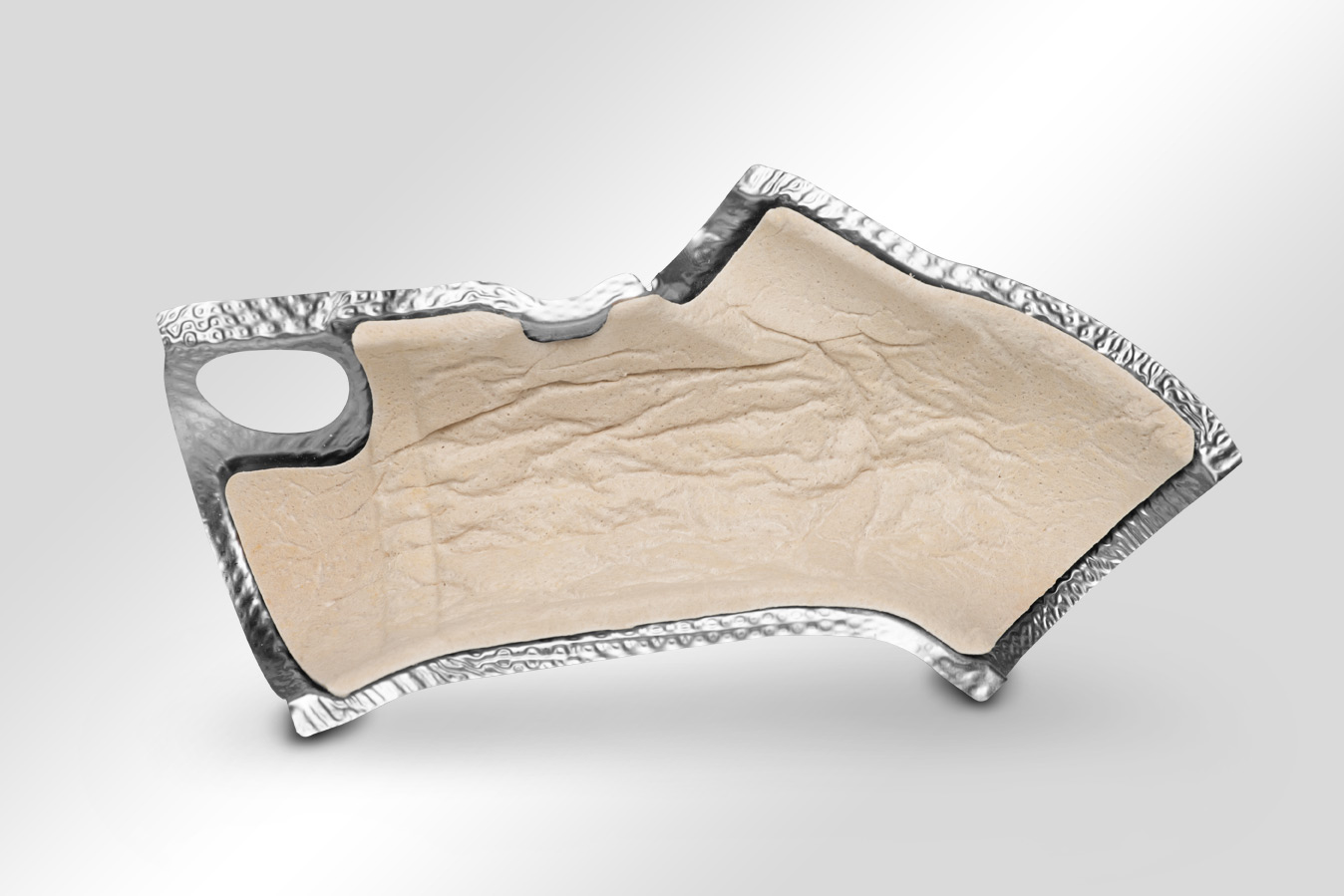

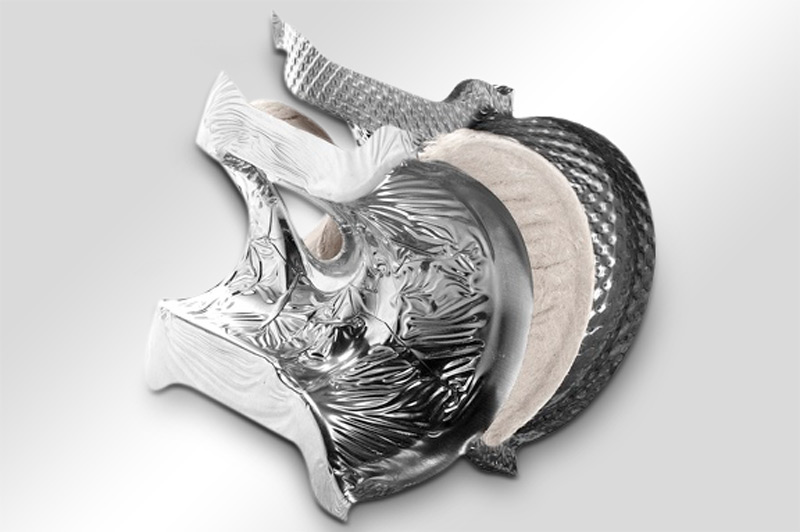

Our iTEX ST insulation shells provide thermal insulation and acoustic absorption for a wide range of uses. Their low thermal conductivity, high sound absorption (ISO 10534-2), high mechanical strength and excellent physical properties are just some of the many benefits iTEX ST insulation shells deliver.

iTEX ST insulation shells are shaped in a special process based on the iTEX mat. With various additives included, a perfectly fitting solution is created that not only boasts improved thermal and acoustic performance but also greater mechanical stability. A 100% reproducible contour makes the skins easy to fit, while neatly sealed pinched edges completely eliminate common welding problems on the metallic lining.

Technical properties

(version depends on application temperature)

| iTEX ST1000

(up to 1.000 °C) |

iTEX ST750

(up to 750 °C) |

iTEX ST600

(up to 600 °C) |

|

| Raw material: | Silica fiber | ECR glass fiber | E glass fiber |

| Filament diameter (nominal): | > 5 μm | 11 – 19 μm | 9 – 13 μm |

| Linear shrinkage: | ≤ 1% | ≤ 1% | ≤ 1% |

| Loss on ignition: | ≤ 1% | ≤ 2% | ≤ 2% |

| Chemical composition (ave. in weight %): |

1. SiO2: 95,0 + – 2,0 2. Al2O3: 3,5 +/- 0,5 3. Traces: < 2,5 |

1. SiO2: 60 +/- 2 2. CaO: 21,5 +/- 1,5 3. MgO: 3 +/- 1 4. Al2O3: 12 +/- 2 5. TiO2: 1,25 +/- 0,75 6. K2O+Na2O: < 1 7. Other: ≤ 2,5 |

1. SiO2: 54 +/- 2 2. Al2O3: 14 +/- 2 3. B2O3: 7,5 +/- 2,5 4. MgO-CaO: 23 +/- 7 5. K2O+Na2O: < 2 6. Other:: ≤ 2,5 |